As the time to start harvesting corn quickly approaches, we have had a few calls about scouting for ear rots and managing mycotoxins.Pre-harvest management of most of the ear rot diseases are to “maintain” optimal growing conditions and manage stress – by planting early, having good fertility, and reducing biotic stressors such as weeds, insects, and other diseases. Unfortunately, this year’s erratic weather has been a challenge due to delayed planting followed by the excessive heat/drought – a perfect scenario for two corn ear rots, and a concern for increased mycotoxin contamination. In this blog, Graduate Research Assistant, Autumn McLaughlin and I discuss concerns, scouting and management for ear rots and mycotoxins.

Two ear rots that are of most concern this year is Aspergillus Ear Rot (AER) and Fusarium Ear Rot (FER). AER is usually observed at the top of the ear with yellow to olive green spores (Image 1).

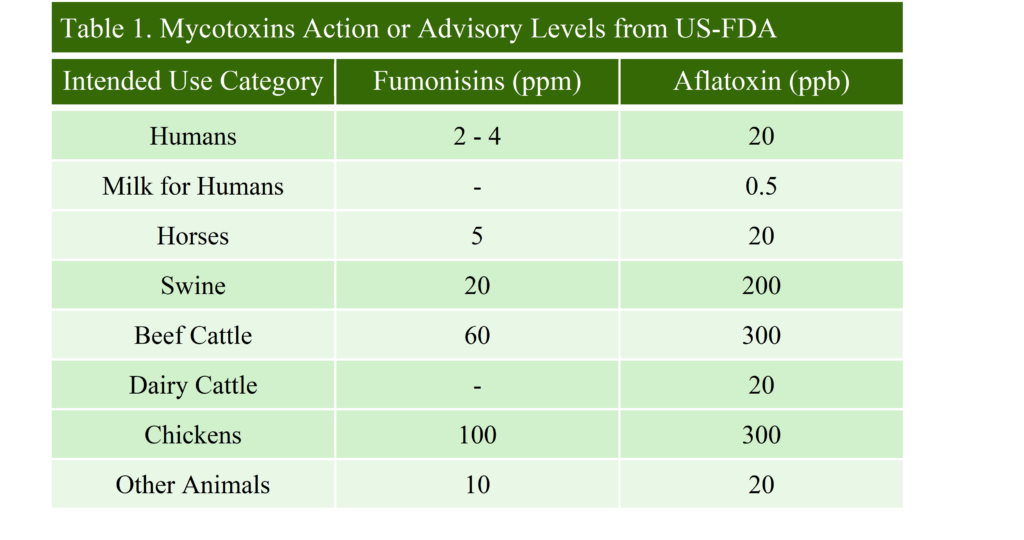

FER can be observed anywhere on the ear and produces purple/peach and white cottony mold, but the most identifying feature is when the kernels look like they have been scratched up in a star-like pattern – known as the starburst pattern (Image 2). While the fungi of these diseases may not have a significant impact on initial yield, mycotoxins produced by them can contaminate grain which pose a risk to humans and animals when consuming the grain – and ultimately decrease crop value or rejection from elevators. Aspergillus produces the toxin known as aflatoxin, which FDA has set action thresholds for (Table 1). This means that when concentrations of aflatoxin reach the level for the intended use, there are legal restrictions on the grain. Fusarium produces the toxin known as fumonisin, which has advisory thresholds (Table 1). Advisory thresholds are meant to strongly caution and provide mycotoxin concentration levels for safety based on the intended use of the grain.

The fungal pathogens that cause AER and FER have been isolated from kernels from research in West Tennessee over the last three years, meaning that the fungi are consistently present in our environment. However, the presence of the fungi doesn’t equate to mycotoxin presence. Environmental factors play a big role in disease and mycotoxin development. Since 2019, we have monitored aflatoxin and fumonisin levels from research plots located at the research stations in Jackson and Milan. During these years, the climate in Tennessee was typical/temperate. That being said, Aflatoxin levels have been extremely low to undetectable in those years – hence the environmental factor being so important. We are aware that Aspergillus is always present in our fields, but it is more likely to produce aflatoxin during extreme heat and dryness experienced during pollination and grain fill. We have consistently detect varying levels of fumonisins in our samples the last few years, with many samples rarely falling below the advisory level of 2-4 PPM for humans. FER can tolerate more moisture than AER, so keep in mind that irrigated fields are still susceptible/at risk. Overall, this year there is a higher likelihood of having aflatoxin in our grain as well as possibly fumonisin.

Right now, if your corn is in the R5/late dent stage, it’s time to start scouting for ear rots and making a harvest plan to mitigate the damage from these rots and their mycotoxins. Being able to identify these specific ear rots can be a sign of potential mycotoxin contamination and can guide your management decisions. To evaluate a field, choose 100 ears (20 ears from 5 different places in the field) and pull back the husk so the ear is fully visible. If more than 10 percent show signs of ear rot, growers should notify their insurance adjuster and prioritize harvesting those affected fields first. Allowing fields to dry down naturally that are at risk for mycotoxin contamination allows the fungi to grow and increase mycotoxin production. You can use the UT Corn Ear Rots and Mycotoxins publication (https://news.utcrops.com/wp-content/uploads/2022/08/Corn-Ear-Rots_Mycotoxins_ExtensionPub2022.pdf) and resources on the Crop Protection Network (https://cropprotectionnetwork.org/publications/an-overview-of-ear-rots and https://crop-protection-network.s3.amazonaws.com/publications/cpn-2001-ear-rots.pdf) to help with identification of ear rots and additional information on mycotoxins, as well as the information on sampling and testing for mycotoxins on the Crop Protection Network publication – https://cropprotectionnetwork.org/publications/grain-and-silage-sampling-and-mycotoxin-testing.

Often damaged and lightweight kernels can be a sign of fungal infection and a recommended management strategy during harvest is to adjust the combine ground speed and cylinder speed to discard these kernels (https://plantdiseasehandbook.tamu.edu/problems-treatments/problems-affecting-multiple-crops/mycotoxins/). Once grain is harvested, it should be dried down – no more than 6 hours after harvesting, until it contains less than 15% moisture or 13% for long term storage. Separate grain affected from ear rots from healthy grain to avoid the risk of contamination. Just to note, drying down and storing at cool temperatures may stop the production of the fungi and mycotoxins, but it does not reduce what mycotoxin is already present in the grain. Mycotoxins are relatively stable compounds that can make it through many extreme conditions – including ethanol production. I had a question about ‘bagging grain’ for storage and if this is an option to mitigate toxin production? The answer depends on how the bag is sealed – the keyword being “Hermetic” or “Air-tight”. Research states that hermetically sealed silo bags can be used to store grain as they provide unfavorable conditions (low oxygen/high CO2) for fungal growth and toxin production. Here is a video further explaining silo bag storage from Iowa State University – Silo or Grain Bags | Iowa Grain Quality Initiative (iastate.edu) and additional information on storage mycotoxin affected grain on the Crop Protection Network (https://crop-protection-network.s3.amazonaws.com/publications/cpn-2004-corn-storing-mycotoxin-affected-grain.pdf). Be aware, however, that proper management of silo-bags is essential for maintaining the hermetically sealed environment and if the seal is compromised then grain is again at risk.