Defoliants work best on mature cotton under warm, humid and sunny conditions. Cool temperatures prior to application and for the three to five days afterward can reduce the activity of defoliant. If possible, defoliants should not be applied during cool snaps. Better defoliation will occur when products are applied during a warm period that is predicted to last for at least three to four days. Sometimes, defoliation may not be justified. Cotton that is completely cutout and naturally shedding leaves may not need defoliation. However, in this situation, it is extremely important to schedule harvest when all dew is off and later in the day to avoid excess moisture. Moduling cotton that has not been defoliated is not recommended unless internal module temperature is checked regularly to avoid overheating. There are many ways to determine proper defoliation timing, but the following have proven to be effective:

NAWF5 + 850DD60’s

((Daily Max Temp. + Daily Min. Temp.)/2) – 60 = Daily DD60

Calculating DD60s after NAWF5 is a good way to gauge crop maturity, but should be used in combination with other techniques. Generally bolls are safe for defoliation after they have accumulated 850 or more DD60s, but some studies have shown that 950 DD60s may be safer. This method usually recommends defoliation sooner than other methods and can sometimes be too early. DD60 accumulation after NAWF should always be accompanied by percent open boll and the sharp knife technique to ensure that premature defoliation does not occur. Early defoliation can reduce micronaire, but it has also shown to reduce yield in many situations. One must first weigh the benefits of decreased micronaire vs. potential yield loss.

Percent Open Bolls

Measuring percent open boll has been the standard defoliation technique for many years and is still the “old standby.” It is generally safe to defoliate when 60 percent of the bolls are open. However, this strategy may not work well in situations where fruit has been set over a varying period of time due to plant stresses. In some situations, defoliation at 60 percent open boll would be premature and cut short the development of the top bolls, therefore reducing yield and micronaire. On the other hand, a crop set in a short period of time could be safely defoliated at 40 to 50 percent open boll. Many producers under-estimate percent open boll and wait until 70-80 percent open to defoliate. Measuring percent open boll from the truck will generally underestimate percent open boll. The best way to determine percent open boll is to measure 3 feet of row in 10 places in the field and actually count open and closed bolls.

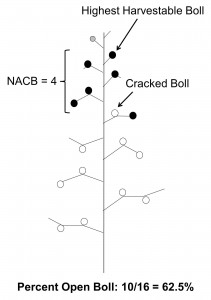

Node Above Cracked Boll (NACB)

To use NACB, find the uppermost first position cracked boll and count upwards on the plant to the uppermost harvestable boll. A NACB of 4 is usually safe for defoliation. However, low plant populations (less than two plants per foot of row) may need a NACB count of 3 to be safe. Low plant populations result in a less evenly distributed crop with high numbers of bolls set on vegetative branches and outer positions of fruiting branches. Once the NACB has been determined, cut the uppermost harvestable boll to inspect the lint and seed. If the boll is mature, then defoliation is safe. If the uppermost harvestable boll is immature, wait until NACB of 3.

Sharp Knife Technique

The sharp knife technique should be used to validate all methods of defoliation timing. Choose the uppermost boll that has a chance of contributing to yield. Make a cross-section of the boll with a sharp knife. Bolls are generally safe when they are difficult to cut and a cross-section of the seed reveals folded cotyledons, absence of jelly and darkened seed coats.

Harvest Scheduling

Defoliation should always be coordinated with picker availability. Applications should be timed so that harvesting can keep up with defoliation. In general, defoliate only as much acreage as can be harvested in about 12 days. Early defoliation of excess acreage can decrease yields, expose lint to weather more than necessary, and increase the likelihood of significant regrowth. When harvesting capacity is low for the acreage involved, consider abandoning the “once-over” strategy and plan to “scrap” or “second-pick” the acreage picked during the first week. This may improve grades and prevent losses should unfavorable weather shorten the harvest season.